It can be difficult for hunting newbies to get a grip on all the knife-related jargon currently being bandied about on the Internet. At first glance, terms like a knife tang, blade design, and knife grind can confuse the beginner.

Contents

What is a Knife Tang

In reality, they are quite easy to tell apart. For example, blade design refers to the shape of the blade and the tasks it is designed for.

Blade grind describes how the cutting edge of the blade is finished. You can read more about these aspects of the hunting knife on my other pages.

Here, I’d like to give you an in-depth tutorial on knife tang. Also, we will discuss some of the most used knife tang types.

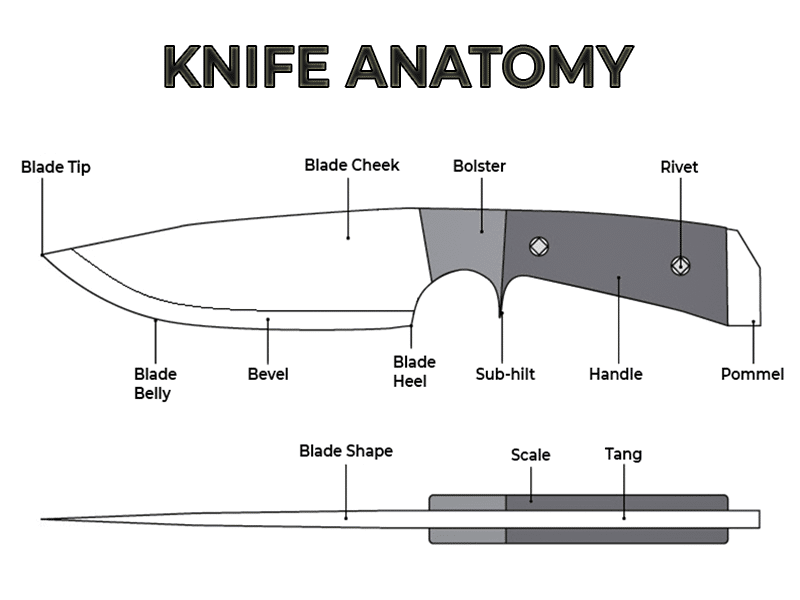

When we talk about knife tang, we mean that part of the blade that extends into the handle. Think of it as the backbone of the knife.

The tang is a crucial part of a knife because it brings the blade and handles together. Without the tang, the blade would separate from the handle as soon as pressure is applied.

There are several different knife tang types, depending on the knife’s style and the kind of handle attached to the blade.

I know a lot of serious hunters insist their knives feature a fixed blade with a full tang. But partial tangs are also very popular and are perfectly adequate for a limited range of tasks.

Difference Between Folding and Fixed Knife Tang

Folding knives also have a tang, albeit a lot shorter. The tang projects just inside the handle and has a pivot to allow the blade to fold.

For reasons of stability and ease of handling, folding knife blades are much shorter than fixed blades. This is why experienced hunters prefer the fixed versions. However, many carry a selection of both fixed and folding knives on the hunt.

This guide will explore all knife tang types, how they’re made, and their advantages and disadvantages.

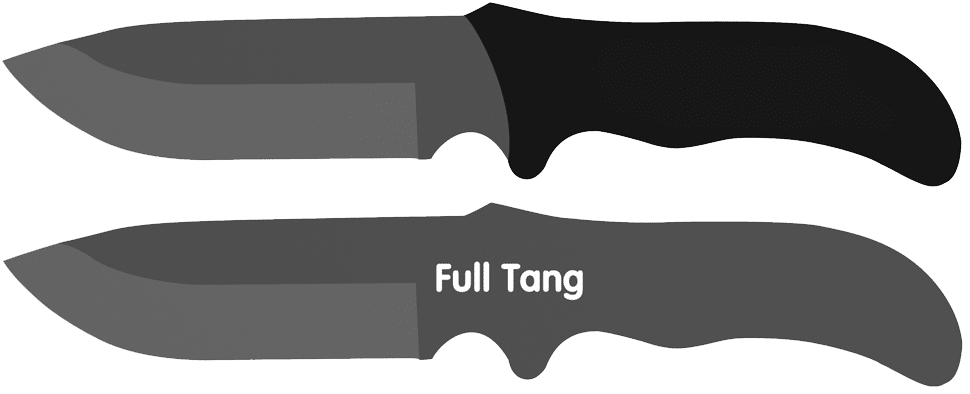

Full Tang

Full tang describes knives where the tang extends through the length and width of the entire handle. It is usually enclosed in two portions of grip material that are held together using epoxy and rivets.

In a classic full tang, you’ll be able to see the metal edge between the two parts of the handle. This means the tang is the same width and shape as the grip.

How It’s Made

Full tang knives are made of one piece of metal, from the blade’s tip to the top of the handle. The tang is machined into shape to fit inside the two-piece grip.

Grip pieces are fixed around the tang with rivets and epoxy to hold them in place.

Uses

Full tang knives are probably the strongest and most hard-wearing type of knife you can get. As a result, they are excellent for heavy-duty tasks and can be brought into action instantly.

Full tangs are ideal in survival circumstances and for hunting procedures where extreme strength and durability are paramount.

Pros

Full tang knives can cope with the strain of large forces leveraged through the handle. Like when you’re chopping wood or when the blade is turning blunt.

A full tang also means that there’s more metal in the handle, which benefits the overall balance. The blade on a hunting knife is often more substantial than the grip, both in length and weight.

The extra mass of a full tang moves the balance point back towards your hand, creating better leverage, balance, and versatility.

Cons

Due to the amount of metal used in their construction, full-tang knives are comparatively heavy.

Also, when the tang on your hunting knife is the same width as the grip, it’s exposed to blood, moisture, and other elements. This makes the full tang prone to corrosion, and eventually, rust. You can avoid this by adopting good maintenance practices!

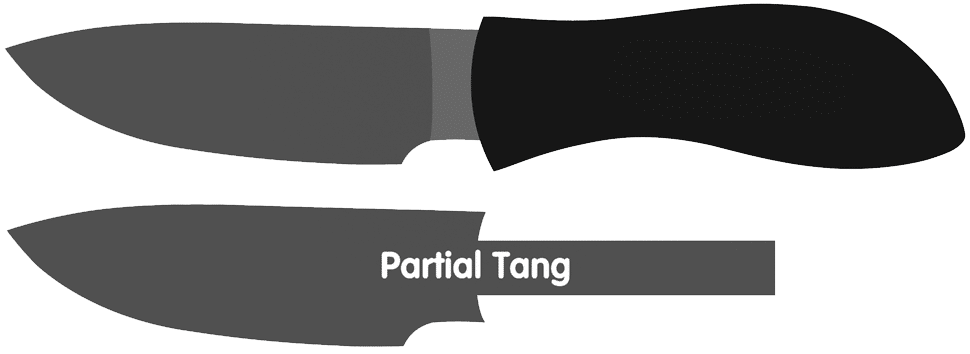

Partial Tang

As the name suggests, the partial tang is where the blade only extends partially into the grip. As such, they are nowhere near as strong as a full tang knife.

Partial tangs also come in various designs, depending on the construction and the intended use. The length of the tang is also quantified according to how far they extend into the handle.

Partial tangs can be three-quarter, half, or stub. Folding knives are also considered partial tang as the shank stops at the handle/blade pivot point.

How It’s Made

Partial tang knives are constructed in different ways, depending on their type and purpose. The tang can be pushed into a ready-made grip, for example. Some tangs are held in place with epoxy, or the handle is molded around the tang.

Some knives have a tang secured by screws with bolt threading to hold the tang in place. It’s worth noting that partial tangs are often a price factor, which is why you’ll find them in the more lightweight, cheaper knives and knives intended for decorative purposes only.

Uses

Knives that need a facility for dull blades to be removed and replaced are partial tang, like scalpels and razors, for example. A lot of regular-use hunting and bush knives are also partial tangs.

Decorative knives and swords that are not intended for actual use are partial tangs too. This is partly because they are not designed to withstand any great external forces, but it also cuts costs.

Pros

The main advantage of a partial tang knife is that it weighs less than a full tang knife. They are ideal for knives with exchangeable blades, and without the partial tang, a folding blade knife just wouldn’t function.

Cons

Although perfectly acceptable for most light uses, partial tang knives cannot leverage as much force as a full tang. They are also prone to break far quicker than a full tang.

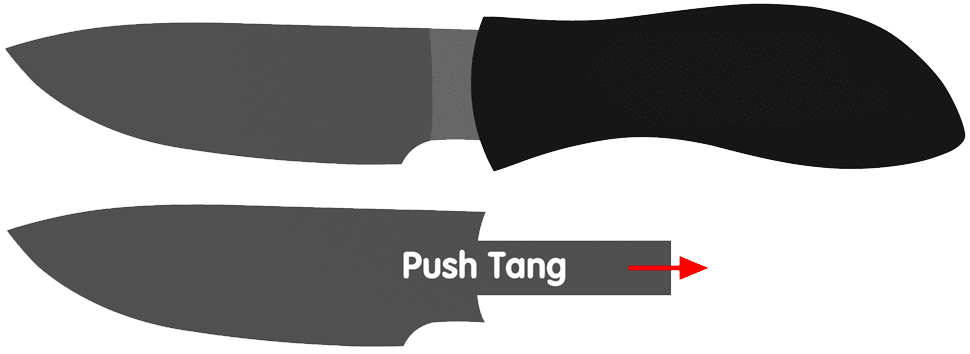

Push Tang

A push tang can be found on both full tang or partial tang knives. The name describes how the tang is inserted into the handle. It’s also sometimes called a “rabbeted tang”.

How It’s Made

This type of tang is “pushed” into a ready-made handle and positioned firmly in place, usually with some type of adhesive or epoxy. This contrasts with the tang being sandwiched between the two halves of a grip.

The tang generally doesn’t extend the full length of the handle, but some manufacturers of full tangs use this method.

Uses

This type of construction is used when a more lightweight or cheaper knife is being made.

Pros

The main advantage of a push tang knife is the reduced cost. This is because it uses less metal than a full tang knife. Also, the tang doesn’t need finishing as it’s not visible.

Cons

Push tang blades can be weak, although modern epoxies have improved a lot over the past few years. Still, there’s always the risk of the tang/handle separating from overuse.

Hidden tang means that the tang is attached to the handle so that one cannot see the tang or how it’s joined.

How It’s Made

Hidden tangs are sometimes made by slipping the tang through a pre-constructed handle until it is flush against the bolsters. The grip of the hidden tang is then sealed with epoxy.

Another method is to make the tang slightly longer than the handle, then use a pommel to hold it in place. Time consuming but more reliable way of doing it is to weld a small projection onto the tang. This is then slotted into a notch inside the handle, which stops the blade from slipping out of the grip.

Uses

The hidden tang method of construction is used when the manufacturer is more concerned with showcasing the handle. Therefore, the functionality and quality of the blade are secondary.

Pros

This method’s big advantage is that it’s strong. It doesn’t fail at the point where the handle meets the tang. It also provides more precise control. The appearance is also a plus. The handle material can be seen to a full advantage on all sides without sacrificing too much strength.

Cons

Hidden tangs are rare on factory knives because they’re harder to manufacture. And while some people say hidden tangs might be as strong as full tangs, I beg to differ.

Hidden tangs lose some of their metal and thickness in the construction process. But it should be noted that hidden tangs are quite reliable, and their strength also depends on the knifemaker.

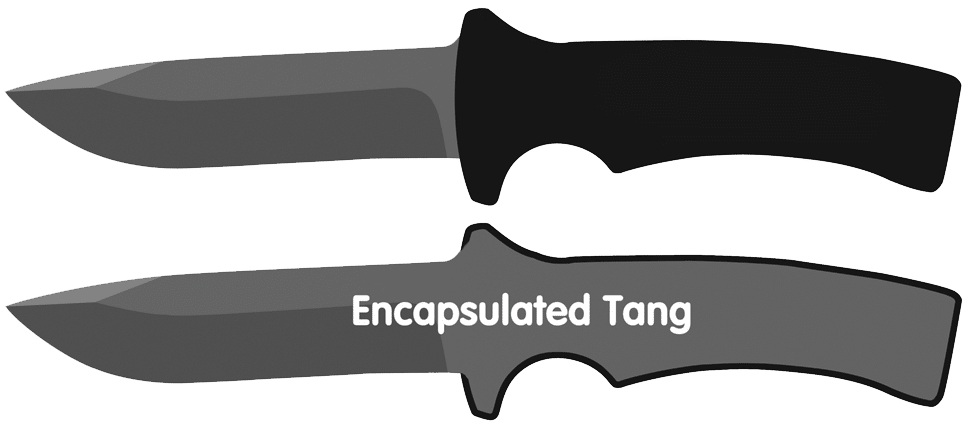

Encapsulated Tang

This type of knife tang is usually very strong and is preferred by many hunters. However, it has its own limitations.

How It’s Made

With this method, the handle material is molded around the tang instead of pushed in. It is then secured in place with epoxy, rivets, or bolts.

Uses

The encapsulated tang is all about aesthetics. It is used when the knife manufacturer wants a push tang’s good looks but requires more strength.

Pros

The main advantage of the encapsulated tang is the strength it offers. Most tend not to fail where the tang meets the handle. They offer a fair amount of accuracy and control as well.

Cons

The success of an encapsulated tang depends very much on the grip of the knife. Which means it can only be incorporated with a restricted range of handle materials.

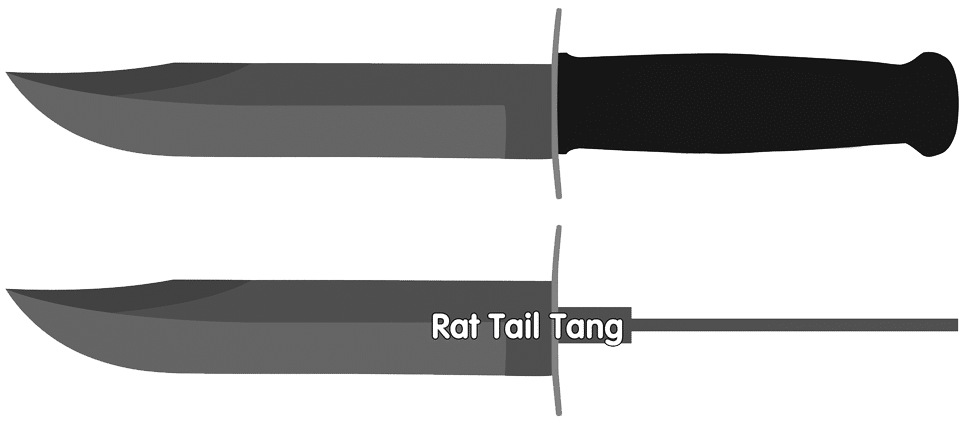

Rat-Tail / Stick Tang

A rat-tail tang gets its name from the blade shape. It’s very narrow, giving the appearance of a rat’s tail, while the blade resembles the rat’s body.

Due to its extreme shape, the tang needs to be attached to the grip by a bolt, rivet, or threaded pommel.

How It’s Made

At the point where the blade meets the tang, the manufacturer abruptly narrows the metal. As a result, rat tails extend the full length of the handle, and then some.

This allows them to be secured by a bolt, pommel, or a rivet on a wired thread that protrudes from the top of the handle.

Uses

This tang design is normally used in decorative knives and swords that aren’t intended for actual use. That said, most rat-tail tangs are up to a lot of the lighter tasks that require less force.

Pros

If all you need is a show or decorative knife, the rat tail is ideal. After all, why spend good cash on a full-tang when you’re not going to use the knife anyway? Knives with this type of tang are inexpensive to produce, and the extremely thin design keeps weight to a minimum.

Cons

Because they’re so narrow, these tangs lack strength. They are not designed for heavy use, and some of the cheapest aren’t even suitable for simple, everyday use, either.

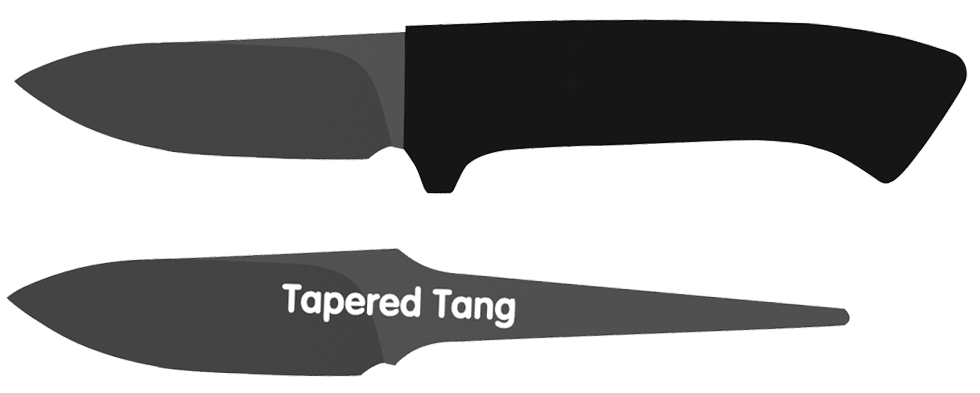

Tapered/ Narrowing Tang

This tang does what it says on the tin. The width decreases gradually (tapers) along the length of the tang. There are several variations. Some may thin along the spine from the blade to the pommel. They may also taper from the spine to the belly.

Another variation tapers from the edges towards the middle. This is a unique way of reducing the amount of steel in the knife handle without sacrificing too much strength.

How It’s Made

The knifemaker will take care to taper the tang gradually to create a good balance. The ‘thinning’ process refers not only to the tang’s width but also to the thickness.

Uses

This is a highly specialized tang, and it is the mark of a custom knife. It’s used mainly to save on material and minimize weight but is also appreciated for its aesthetic value.

Pros

Tapering saves material, and therefore cost, as well as weight. Additionally, it creates a well-balanced knife. This method shows off the knifemaker’s skill and attention to detail.

Cons

Tapering the tang’s width and thickness is quite a skill. But in my opinion, it creates a flawed knife. That’s because when the width is reduced, what was a perfectly good tool is weakened.

Under extreme uses, this may cause failure. Still, very nice as a collector’s piece.

Skeletonized Tang

Skeletonized describes tangs where portions are cut out from the center of the tang, reducing the amount of material. Knives made like this often have no grip material at all or simply a cord-wrapped handle.

How It’s Made

The first inch or so of the tang is usually the weakest part, so that’s left well alone. From there, the material is removed from the center area.

Uses

These blades are useful when a good balance is desired, and low weight is a definite requirement. Skeletonized tang knives are mostly used as throwing knives.

Pros

Removing excess steel from the center of the tang helps retain some of the full tang’s strength. It also offers a reduction in overall mass.

This improves the knife’s balance. Plus, removing the middle allows the epoxy to fill a greater surface area inside the grip. This adds stability and reliability to the knife.

Cons

Skeletonized tangs are weaker than real full tangs. How much weaker depends on where the spaces are cut. The difference in strength does not have to be excessive if done correctly, which is often the case with the better quality skeletonized tang knives.

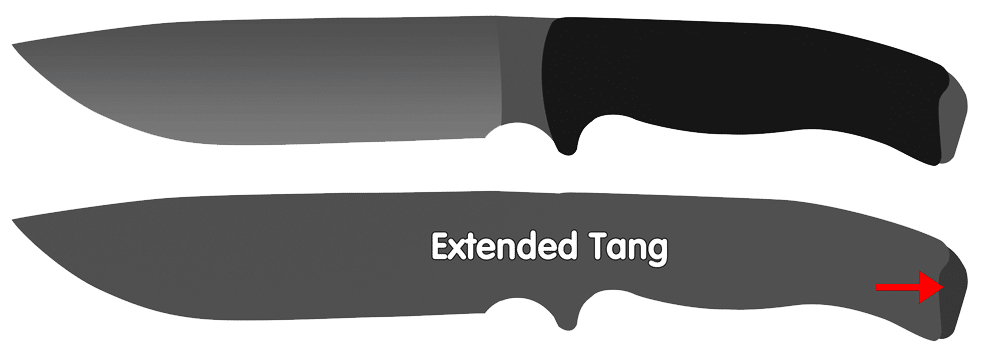

Extended Tang

Usually, knife tangs stop at the end of the knife grip or before it. An extended tang sticks out from the end of the handle. The part of the tang protruding from the handle can be used to fix the tang, but also as a hammer pommel.

How It’s Made

The tang is made longer than the handle. It is usually rounded or shaped to form an attractive, safe, and comfortable end to the knife.

Uses

The extended tang can be used as a hammer. For example, to hammer in tent pegs, crack open nuts. Some also come with a hole for a lanyard.

Pros

Not to be mistaken for a serious tool, but the pommel can come in handy for some minor tasks. Some people enjoy this as an extra feature.

Cons

There are no significant cons when it comes to having an extended tang. The design might influence or restrict the kind of material the handle can be made of. But if the rest of the knife works well, why not?

Which Knife Tang is the Best?

As with all aspects of knife design, the tang is mostly a matter of individual preference. It all comes down to what you need the knife for and your expectations of that knife.

How much you want to spend is also a factor. Understandably, a full tang knife will be more expensive than a partial tang knife. The length of the handle is also a pricing factor.

Drawing on my own experience, all of the tangs I talk about here, if crafted carefully, will last longer and provide good service. Provided, of course, they are properly maintained and used for the purpose for which they were designed.

Of course, each tang comes with its own pros and cons. Before you decide which one is right for you, always examine the finish and balance of the knife as a whole before making your choice.

Hi, my name is Michael Goodman. As a skilled hunter and a man of the field, I will show you some sophisticated, intelligent, and useful hunting methods and techniques.