To sharpen the edge of your knife blade may seem simple. But, there is a lot involved in the proper knife sharpening process.

For instance, there are a variety of blade steels and different types of blade grind. All of which require different honing angles and different grits.

You also need to know the type of sharpener to use on your knife. A pocket sharpener will most likely be used on bushcraft or field knives since you’ll have them out in the field.

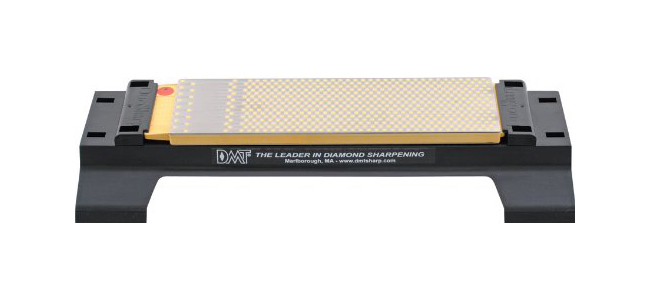

It’s also vital to get a proper whetstone for the job at home or in your workshop. Although the process may seem complicated, it’s worth mastering. It’s an integral part of keeping your knife ready for use.

Need to know more about the difference between a saber grind and a flat grind, an oil stone and a water stone, an Arkansas stone, and an India stone?

Then keep reading to discover more on how to sharpen a hunting knife.

Contents

What are Whetstones?

To define it simply, a whetstone is a fine-grained stone that hunters use to sharpen and cut different types of tools.

Before looking at the actual knife blade’s edge honing process, let’s begin by examining the nature of the available whetstones.

Whetstones are used to sharpen a hunting knife and are categorized into two different groups.

The first group consists of naturally occurring stones, such as Japanese water stones and Arkansas oil stones.

The second group contains man-made stones, like the India stones (silicon carbide), and aluminum oxide, also known as crystalon.

Both natural and man-made whetstones are classified as either oil stones or water stones. It means that you can use them with either oil or water as a lubricant.

However, some man-made whetstones such as ceramic and diamond can be used with or without lubricant.

Also, both whetstone types exist in different grits. Finer grits are less abrasive, while coarser grits are more abrasive.

Different knives exhibit different types of blade grinds and require different sharpening angles to achieve the proper edge type.

Types of Whetstones

Japanese water stones are mined in the mountains of Japan. The stones are made of ancient metamorphic rock deposits consisting of tiny silicate particles.

They are suspended in a clay matrix, and as a result, produce fine crystals every time you sharpen with them. These fine crystals sharpen the knife by removing ultra-thin layers of steel, as well as polishing the surface.

Arkansas oil stones are mined in the Arkansas mountains. These stones come from ancient novaculite deposits, thought to be a type of metamorphic sandstone.

Novaculite is highly effective for quick steel removal. It also produces fine crystals during the sharpening process. These also ensure that the surface stays polished.

There are also man-made whetstones available. They are made from silicon carbide (impregnated ceramic) and powdered industrial-grade diamonds. These stones require no lubrication.

Types of Blade Grinds

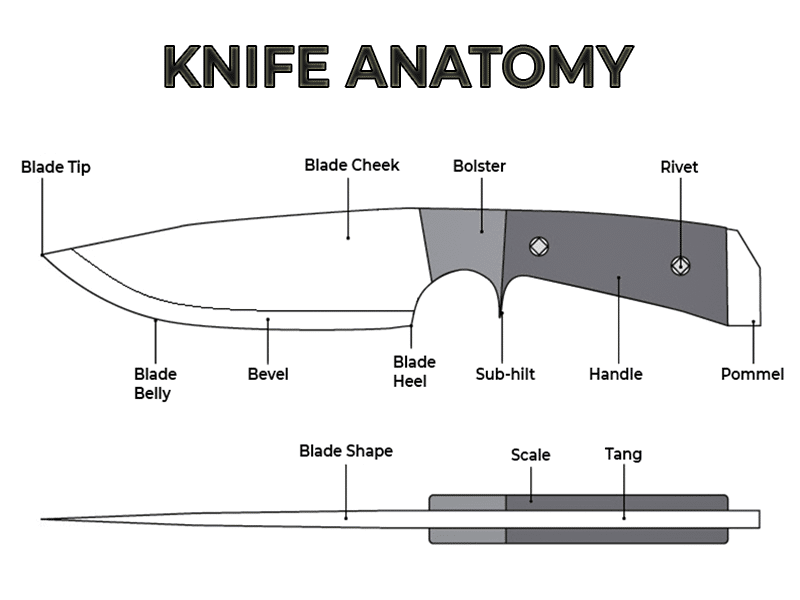

Each knife has a specific way the blade has been ground and how to sharpen it. The ground surface is called the bevel. The primary bevel is the largest and most visible edge.

The line that descends from the back of the primary bevel to the back of the cutting edge is the plunge line. The spine is the widest cross-section of the knife.

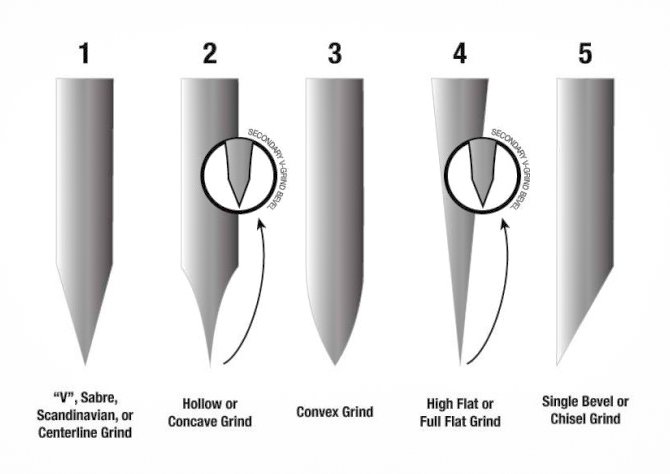

Now that you have that terminology under your belt, you should also know that a saber grind is a type of blade grind whose primary bevel line is low on the blade’s face, close to the cutting edge.

A hollow grind is similar, but its primary bevel is higher on the blade’s face. It is distinctly concave, creating a relatively thick primary bevel.

A flat grind has no primary bevel line because the blade’s face is ground flat from the cutting edge to the spine. Thus, creating a tougher edge than a hollow grind and one that’s sharper than a saber grind.

Hunting knives generally have hollow grinds, while knives meant for general use have flat grinds.

Heavy-duty use knives have saber grinds. It implies that blades with saber grinds need to be held at a higher angle when sharpening (25 to 30 degrees) than hollow or flat grind blades. This is to enable the blades to withstand the shock generated by chopping.

Similarly, blades with hollow grinds need sharpening at much lower angles, ranging from 10 to 15 degrees.

When it comes to blades with flat grinds, sharpening is to be done at angles between the two—and largely depends on the thickness of the blade’s spine.

Blade Steel Grinding Tips

It’s important to note that the various blade’s steel types and their Rockwell Hardness require different grits. In some cases, even different whetstone materials – when it comes to sharpening.

For instance, knives with relatively soft blades generally make large and heavy blades with saber grinds. Although these blades get sharp relatively quickly, they’re also susceptible to damage. Especially on the edges, and hence need frequent maintenance.

Remember to start with a coarse grit before proceeding to the finer grit when sharpening a knife with a softer steel saber grind.

Do leave the edge rough, though. Otherwise, it will blunt quickly the next time you use it.

When it comes to knives with fairly hard blades with either hollow or flat grinds, consider starting with a medium grit and then proceeding to fine grit.

If the blade has a hollow grind with a particularly thin primary bevel, you may want to consider polishing the cutting edge with an extra-fine grit.

Regardless of the type of whetstone you choose, the knife sharpening process remains the same.

Depending on the whetstone type you decide to use, you’ll usually first need to lubricate it with honing oil or water, after which you’ll begin the sharpening process.

To begin sharpening your blade, grasp the knife by the handle and place the edge against the whetstone at a 10 to 30-degree angle, depending on the primary bevel’s thickness.

After that, slowly begin to move the entire cutting edge length across the whetstone while maintaining the same angle.

Then, turn the blade and do the same on the opposite side. Repeat the process for both sides until you achieve the desired sharpness.

If you find it difficult to maintain a consistent angle during the honing process, consider getting yourself a honing aid to enable you to achieve a fine edge with any type of knife blade.

Wrapping It Up

The knife sharpening process begins with choosing the right type of whetstone in the proper grit. It all depends on the type of steel that your knife’s blade is made from, as well as its Rockwell hardness.

The correct honing angle is largely determined by the secondary bevel’s relative thickness determined by the blade grind type.

Man-made whetstones like India and crystalon stones are the most affordable. They work well for the quick repair of damaged edges and cutting initial secondary bevels.

On the other hand, natural whetstones like Arkansas oil stones and Japanese water stones may be a little costlier, but they do a better job for edge sharpening.

Ceramic whetstones and diamond stones come in handy if you find it inconvenient to lubricate the whetstone before use.

Regardless of the type of whetstone you choose, the key step to achieving a super-sharp edge is to keep the angle at which you hold the blade at the same level through the sharpening process.

Hi, my name is Michael Goodman. As a skilled hunter and a man of the field, I will show you some sophisticated, intelligent, and useful hunting methods and techniques.

WOW! That’s a great article.

Thanks!