A good knife is nothing without a good handle.

The blade could be from the highest-quality steel and have an unbelievably sharp edge. But if the knife handle material is poor, it will be much harder to use the knife.

Contents

What’s a Knife Handle?

Knife handles are an essential yet often underappreciated part of a good hunting knife, and you need to know how to find a good one.

A bad handle can make even the highest quality metal blade not fun to use.

Many people don’t realize that knife handles have different materials, and there are many options to choose from. You might get overwhelmed if you are shopping around without any information.

Today, we want to talk about the ins and outs of blade grip materials and give some pointers on how to pick the best ones.

We will cover some of the most common knife handle materials and discuss their pros and cons. We will also consider which handle material types are best for what kind of knives.

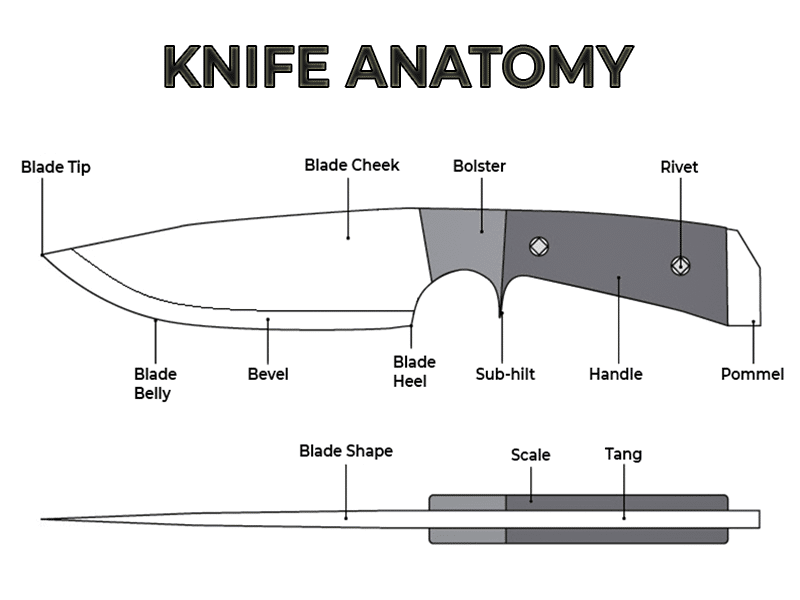

Just for clarification, when I talk about a knife handle, I refer to the part of the blade that covers the knife tang.

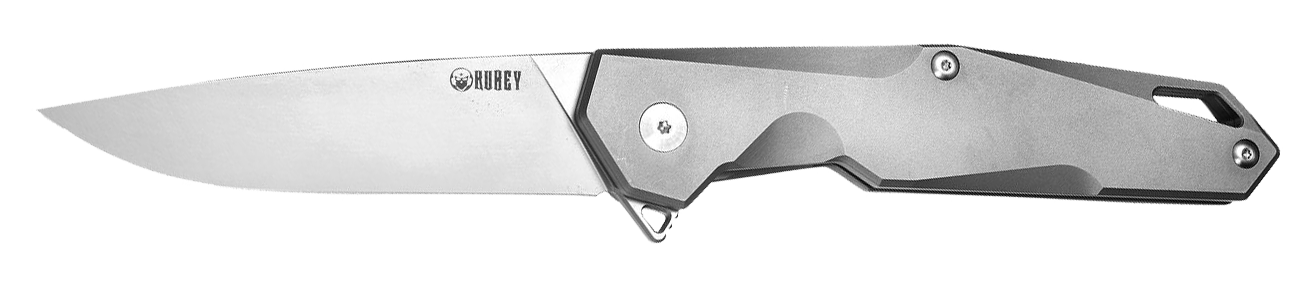

Stainless Steel Handle

Stainless steel is one of the more popular materials to use because of its durability and resistance to rust and corrosion.

It’s also resistant to scratching and does not flex much at all. That way, the handle remains firm in your grip.

Stainless steel can get wet and slippery when moist or wet. Therefore, steel handles normally include raised ridges or small rubber pieces for grip.

The main drawback of stainless steel is that it is typically heavy. That’s why a large knife with a steel handle can have an unbalanced feel.

As such, stainless steel handles are generally not a good idea for EDC or heavy-duty knives. It makes them too weighty to wield effectively.

One other benefit of steel is that it is very easy to clean. Steel can handle most common cleaners and will not stain like wood or some plastics might.

So if you use your knife to dress game, for example, you won’t have to worry about bloodstains. Overall, stainless steel is probably best for smaller folding models and buck knives.

Pros

- Stainless steel is highly durable and resistant to common hazards you will find out in the wild like water and corrosion.

- Very rigid, it will not deform under your grip even when grasping tightly.

- Easy to clean and resistant to staining and discoloration.

- Great handle material for smaller folding models.

Cons

- Steel is fairly heavy. Larger knives with a steel handle might be off-balance.

- Steel can get slippery when wet and reduce grip.

- It’s not as comfortable as compared to some other materials.

Aluminum Handle

Aluminum is another popular choice for blade handle material. It is highly durable, anodized and resistant to corrosion, and very lightweight for a metal. It’s also relatively low-density but has a solid, weighty feel to it that makes a balanced handle.

Most aluminum handles nowadays are explicitly made out of T6-6061 alloy. It is composed of aluminum, iron, manganese, titanium, chromium, and several other metals.

Aluminum is a good material that can provide a solid grip. Like steel, aluminum can get slippery from moisture, so it often incorporates raised textures and plastic/rubber pieces to provide more friction.

Aluminum alloy is also not very ductile, meaning that it will not bend or deform under pressure like some metals can. However, it will scratch or ding.

One drawback of aluminum is that it is highly conductive. As a result, it can get very hot during the summer and very cold during the winter.

That also means that aluminum conducts electricity very readily, so you will not want to use it around any wires or electrical sources. Aluminum is used as a material in a lot of knife models because it is flexible and versatile.

Pro

- Aluminum has an excellent weight to durability ratio, so it is tough but not too heavy.

- Aluminum has anti-rust and anti-corrosion properties.

- T6-6061 alloy, the most common type of aluminum alloy, has an incredibly high tensile strength.

- Aluminum is relatively inexpensive if compared to other metals.

Cons

- Aluminum is conductive and so can get very hot or cold, depending on the temperature.

- The metal will scratch or ding.

- Bleach and other strong cleaners can change the color of aluminum alloy.

Titanium Handle

When it comes to metal knife handle materials, hunters consider titanium the best.

It has a ridiculously high tensile strength, is essentially impervious to rust and corrosion, and has an excellent weight to durability ratio.

Titanium is one of the strongest metals per weight on the planet.

However, it is usually more expensive to manufacture. It’s heavier than aluminum but also lighter than stainless steel.

The alloy quality measures in “grades.” Grade 5 titanium is the most common type for knife applications and incorporates trace amounts of aluminum and vanadium in its molecular structure.

Titanium is also less conductive than either steel or aluminum. It does not get as hot or cold when in extreme temperatures.

Titanium has a bit of “springiness” to it despite its immense tensile strength, so it is comfortable to hold.

Titanium can also be colored through an anodization process and is textured through bead-blasting to create grips. It’s relatively ductile, though, and will scratch and ding if hit with other hard materials.

Pros

- Titanium is very lightweight and has an extremely high tensile strength.

- Titanium is one of the most corrosion and rust-resistant metals on the planet.

- The metal has an excellent weight to durability ratio and balance.

- It is usually anodized to create bold, custom colors.

Cons

- Titanium is relatively expensive to manufacture and produce.

- Despite the strength, titanium will scratch or ding.

- Be wary of low-grade titanium alloy; marketing tactics may obscure the actual quality of the alloy.

G-10 Handle

“G-10” is a type of composite material that consists of fiberglass laminate. It’s manufactured through bathing layers of glass cloth in epoxy resin and compressing until the epoxy hardens.

G-10 is actually structurally similar to many other types of composites such as Micarta and carbon fiber, just different components.

The g10 handle material is actually very cheap to manufacture and has high tensile strength. As such, it is commonly used in industrial applications.

G-10 composite is not metal, so it has very low conductance and resists heat, cold, and electricity. It is relatively low-density and lightweight, so it is commonly used for tools, including firearms and handles for knives.

G-10 is also moisture resistant, so it does not get slippery when wet and will not corrode due to water damage like some natural materials will. Also, it’s fairly smooth and so is etched or bead-blasted to create grips.

When shaved down, G-10 will create airborne particles that can be harmful to your lungs. So if you like to make custom grips, make sure you have mouth protection when grinding G-10.

Pros

- The manufacturing process is relatively inexpensive, so G-10 is often pretty cheap.

- G-10 is resistant to heat, cold, and electricity because it has low conductivity.

- Resistant to water and moisture, so it does not get very slippery when wet.

- Excellent strength to durability ratio.

Cons

- G-10 is brittle and can crack and fracture under pressure.

- The material can become discolored from sunlight and extended UV exposure.

- G-10 creates a hazardous airborne substance when ground and shaped.

Carbon Handle

“Carbon fiber” is the generic name for any kind of resin material that is set with strands of carbon. In other words, it’s a special kind of polymer resin that is reinforced with carbon chains.

Carbon fiber has an extremely high tensile strength. It is actually significantly stronger than steel per unit weight and is much lighter than most metals.

Carbon fiber is also a good insulator, so it does not conduct heat, electricity, or cold very well.

While carbon fiber has a very high tensile strength, it is still a relatively brittle handle material and can crack and shatter if subjected to the right kinds of forces.

Specifically, sharp impacts perpendicular to the surface can cause it to crack and shatter.

Carbon fiber is also favored because it can make unique custom color designs. The molecular structure of carbon fiber reflects light in a unique pattern.

That’s why you can get a cool glossy-like finish from a carbon fiber handle. As I said, it’s not very cheap; you’ll have to pay a bit more for a carbon knife handle.

Pros

- Carbon fiber has immense tensile strength and is very durable and lightweight.

- The material is a great insulator and resists heat, cold, and electricity.

- Carbon fiber “weaves” can create cool optical effects.

- It’s warm and comfortable to grasp and has a certain “spring” to it.

- It will not degrade from UV exposure.

Cons

- Brittle; can crack if subjected to the right kinds of impacts.

- It’s expensive to manufacture and produce.

Micarta

Micarta is another synthetic knife handle material. It is sometimes called a phenolic, which is the term for any material made out of phenol.

In addition, Micarta is an excellent insulator and was first used as an insulator in electrical systems.

Micarta is made out of layers of linen soaked in resin and compressed until the resin fully dries. The resulting plastic-like material is lightweight, tough, and has a nice, glossy finish.

Micarta is very smooth and glossy when created, so it needs to be ground and shaped to make a knife handle.

This process takes a fair amount of work, which is why Micarta is generally on the more expensive side of the spectrum. It is definitely worth it, though; Micarta is very strong, resistant to scratches and abrasions, and resistant to impact damage.

Micarta also will not discolor from UV exposure and can handle the toughest cleaning solutions. Although strong, Micarta is brittle, so it may crack or fracture if it’s hit hard enough.

Pros

- Micarta is lightweight, extremely durable, and is low-density; It’s also balanced and strong.

- Composite materials are highly resistant to water, corrosion, and weathering.

- Micarta is a good insulator and resists heat, cold, and electricity.

- Creates cool optical effects.

Cons

- Carbon fiber is relatively expensive to produce and manufacture.

- Polymers, in general, are brittle and will crack and fracture from sharp impacts.

- Can be slippery if not textured with a pattern or extra grip material.

Zytel Handle

Zytel, also known as Fiberglass Reinforced Nylon (FRN), is a special kind of plastic initially used in industrial chemical applications.

It is made from bundles of nylon strips encased in a tough polymer resin material heated and compressed to solidity.

The nylon fibers are arranged in a complex lattice, facing multiple directions. As a result, Zytel has equal tensile strength in all directions instead of just a principled direction.

Zytel is also relatively inexpensive to manufacture. Many critics complain that Zytel feels “cheap” and “hollow”, but it has decent durability and a good weight to strength ratio.

The secret behind the low price point is that injectable molds are used to mold and set the material, making it easy to shape and produce.

Keep in mind that Zytel is pretty flexible for a knife handle material, so that many companies may put a unique spin on their nylon composites.

For example, some companies might reinforce their FRN with carbon strings, making it stronger. Other companies may settle for a cheaper, less modified Zytel.

Pros

- Zytel is highly resistant to heat, cold, corrosion, chemical weathering, and degradation.

- This material is inexpensive to manufacture and is easily customizable.

- Nylon fibers provide strength in all directions instead of a preferred direction.

- Easy to clean and maintain.

Cons

- Plastic might feel gummy or cheap.

- Grip has a bad tendency to wear down over time.

- It’s not incredibly environmentally friendly to manufacture.

Wooden Handle

Wood is probably one of the first materials in history used for knife handles and is still popular with several hunting enthusiasts.

Wooden handles are attractive, have a nice “rustic” charm, and will actually change shape to fit your hand better over time.

Wood is also comfortable to grasp and can be carved into unique, decorative patterns.

Manufacturers use several types of wood for a knife handle, so you need to make sure you pick one with decent quality.

Most wood knife handles are from natural deciduous hardwoods, while some are from stabilized wood.

Stabilized wood is dried and mixed with chemicals to enhance its strength and fix imperfections.

Some of the best types of wood to use for a handle include walnut, birch, oak, rosewood, cocobolo, ebony, and burl.

These woods are recognizable for their strength, hardness, attractive natural appearance, and coloring.

Hardwood handles tend to be more expensive than stabilized wood, but it is higher quality and lasts longer.

The main drawback of wood handles is that they can be porous and insatiable. Even if you seal the handle, it can still let moisture in and degrade over time.

Pros

- Wood has an attractive natural finish that looks great.

- There are a ton of wood varieties to pick from, each with strengths and weaknesses.

- Wood is comfortable and will slowly shape to your hand over time.

- Wood is a good insulator and resists heat, cold, and electricity.

Cons

- Wood is porous and readily absorbs moisture.

- Even the strong types of wood are weaker than metals.

- Wood will scratch and dent relatively easily.

Rubber Handle

Some knives also use rubber as their handle material.

Generally, rubber handles are not pure rubber. They include a solid center attached to the blade that is then covered in rubber.

Rubber is a useful material for all kinds of applications as it is strong, resistant, flexible, and is a natural insulator.

Several varieties of rubber are also cheap to manufacture, so it’s not that expensive.

The most common type of rubber used for knife handles is neoprene rubber. Neoprene is made from a material called “chloroprene” and has a good ratio of tensile strength to density and hardness.

Neoprene rubber is also non-reactive, so it’s resistant to corrosion and degradation.

Moreover, rubber is comfortable to hold, warm, and has good friction. Some people think that rubber handles have too much flex and prefer a harder handle.

Rubber, however, is vulnerable to tearing and cuts. It has good tensile strength but can be cut relatively easily with sharp edges. Some types of rubber are slippery when wet.

That’s why manufacturers often make rubber ridges for grip.

Pros

- Natural and easy to manufacture. Rubber is fairly cheap to buy.

- Rubber is highly stretchy, resistant to most types of chemicals, and insulates against heat, cold, and electricity.

- The rubber is soft and comfortable to grasp.

- Has a certain amount of “flex” that some people like.

Cons

- Rubber can be punctured or cut by sharp edges.

- UV exposure can discolor rubber and break it down.

- Rubber expands and contracts based on external temperatures.

Bone Handle

As is the case with wood, bone has been used as a knife handle material throughout all history. In addition, bone has some interesting properties that make it a useful handle material.

First off, bone is incredibly strong for its weight. It has a neat, rustic kind of charm to it.

Bone has a unique cellular structure that is pound for pound stronger than concrete while being just a fraction of the weight. It’s also highly resistant to weathering, corrosion, and electricity.

Bone handles consist of bones from all kinds of animals, including elephants and giraffes. However, most bone handles are from cow bones or antlers, which are cheap and abundant.

The bone is usually bleached, cleaned, and polished, so it is bright and smooth. Many manufacturers will also dye bones to get a bright color.

Bone handles look great and are comfortable to hold, but they are sensitive to temperatures and absorbs moisture. Bone will also get slippery when wet, so you shouldn’t use it for heavy-duty knives.

Lastly, heavy UV exposure can bleach bone and cause its color to fade. That being said, many people prefer bone handles because they have a nice, traditional feel to them.

Pros

- Bone is light and has an exceptionally high weight-to-strength ratio.

- It’s relatively inexpensive and cheap to make. However, some creators make intricate carvings that take a lot of manual labor.

- Bone handles look great and have a natural flair.

Cons

- Bone will absorb moisture and is sensitive to temperature change.

- Stress and pressure can fracture bone and cause it to deform.

- Bone will wear down over time from your grip.

Hi, my name is Michael Goodman. As a skilled hunter and a man of the field, I will show you some sophisticated, intelligent, and useful hunting methods and techniques.